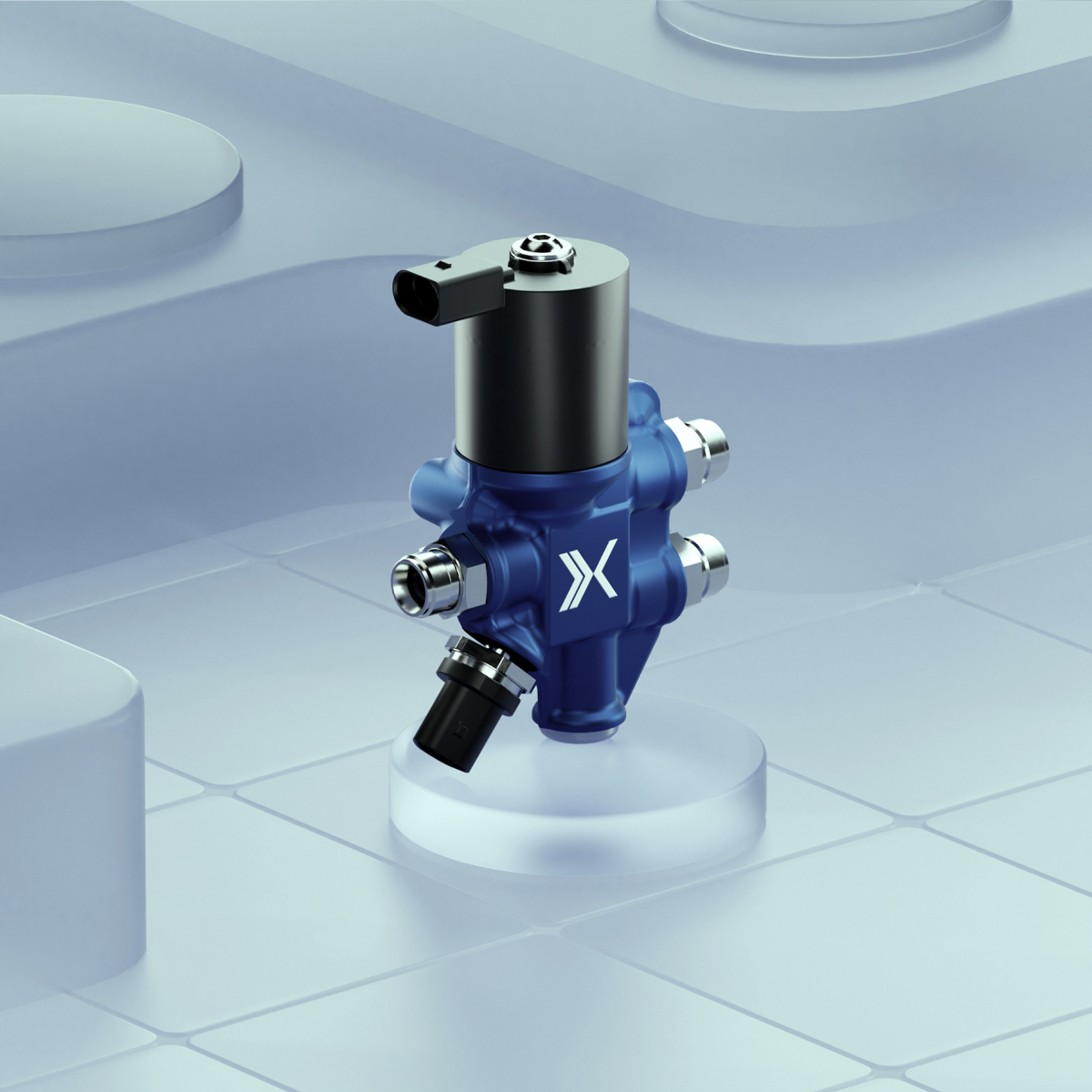

From concept to serial production

R&D project house,

prototype-manufacturing and test bench under a single roof

Agile

development

process

Our innovation hub is designed for an agile and flexible development process, the communication between our cross-functional teams is fast, pragmatic and effective.

The close cooperation and short distances between our project house, prototype-production and testing area allow us to save time and costs.

Within a few hours, the concepts developed by our R&D are converted into prototypes and then evaluated on our in-house test bench.

Precise and

fast prototyping

The concepts developed by R&D are drawn in 3D and immediately converted into workshop drawings for our prototyping department, where our CNC machines quickly bring the ideas to life in the form of high-quality product samples. This allows us to be independent of suppliers and to incorporate the know-how we gain through prototyping into the series product.

Reliable

testing

The manufactured prototypes are then assembled, evaluated, optimized and further developed on our test benches. Having an in-house, self-designed testing equipment with integrated measurement technology offers us the great advantage of reacting fast and rapidly implementing any adjustments.

Our devices have the capability to test with different liquids, such as air, helium, nitrogen, liquid nitrogen, and CO2.